While plastics have forever changed the way we live, the story isn’t always as rosy as the American Chemistry Council infers in the quoted slogan.

Introduced in 1956, acetal (also known as polyacetal, polyformadehyde or polyoxymethlene) was developed for high stiffness, low friction and stability. This material was successfully used in the manufacture of automotive parts such as cams, bearings, gears, etc. But in the 1970’s acetal was introduced into plumbing systems, with disastrous results. Over the last 30 years, acetal plumbing parts have shown a high failure rate, resulting in billions of dollars in property losses.

Publicized failures of acetal plumbing parts were seen in the 1980s. Acetal was used to fabricate fittings incorporated into residential water supply piping made of Polybutylene ("PB"). Homes across the country were suffering PB water system failures, causing water losses. Class action litigation ensued, with one of the largest in US history (Cox v. Shell Oil Co., et. al) settling for $950 million. A cause of the PB piping failures was degradation of the acetal fittings, which led to fracture and water release.

Publicized failures of acetal plumbing parts were seen in the 1980s. Acetal was used to fabricate fittings incorporated into residential water supply piping made of Polybutylene ("PB"). Homes across the country were suffering PB water system failures, causing water losses. Class action litigation ensued, with one of the largest in US history (Cox v. Shell Oil Co., et. al) settling for $950 million. A cause of the PB piping failures was degradation of the acetal fittings, which led to fracture and water release.

Acetal plumbing fittings resurfaced in the 1990s. This time, acetal was formed in fittings incorporated into flexible water supply lines manufactured by various companies, including Robert Manufacturing, Watts Industries and Fluid Master). Failures began to surface in late 1990 and 2000. The failures had a similar appearance, with the plastic coupling fittings suffering cracking or full fracture. .jpg)

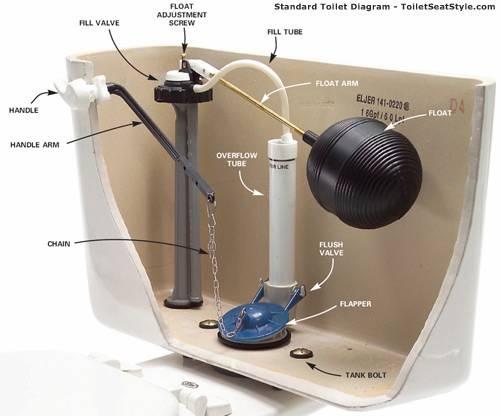

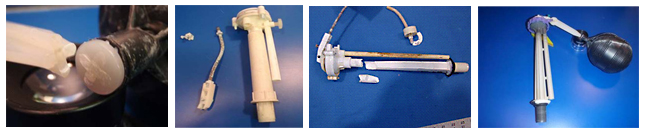

More recently acetal failures have arose in toilet valve assemblies, including those manufactured by Coast Foundry and Fluid Master. Acetal was used in certain models to fabricate the toilet valve shaft, float arm and trigger.

There are two primary causes of these failures. Acetal has been recognized within the plastics industry since as early as the 1950’s to be sensitive to acid hydrolysis (a chemical reaction during which one or more water molecules are split into hydrogen and hydroxide ions) and oxidation (the addition of oxygen to a compound with a loss of electrons) by agents such a chlorine. And since chlorine is a required additive for virtually all domestic water systems, degradation of acetal plumbing products is an all to frequent occurrence. Low levels of chlorine in potable water supplies can be sufficient enough to cause stress corrosion cracking (sudden failure of normally ductile metals or tough thermoplastics ) to develop, a problem which has been experienced in both the USA and Europe. Acetal is also notch sensitive, meaning the materials susceptibility to fracture. Acetals have the highest crystallinity (degree of structural order in a solid) of any thermoplastics making it strong and fatigue resistant. This toughness (or lack of ductility) makes it susceptible to fracture where there is a notch, a sudden change in the surface section, a crack, or scratch. Because acetals are notch sensitive, sharp corners must be avoided in part design. This has been an issue in various acetal product designs, including the thread geometry of the water supply coupling nuts and toilet valve triggers, resulting in premature failures.

There are two primary causes of these failures. Acetal has been recognized within the plastics industry since as early as the 1950’s to be sensitive to acid hydrolysis (a chemical reaction during which one or more water molecules are split into hydrogen and hydroxide ions) and oxidation (the addition of oxygen to a compound with a loss of electrons) by agents such a chlorine. And since chlorine is a required additive for virtually all domestic water systems, degradation of acetal plumbing products is an all to frequent occurrence. Low levels of chlorine in potable water supplies can be sufficient enough to cause stress corrosion cracking (sudden failure of normally ductile metals or tough thermoplastics ) to develop, a problem which has been experienced in both the USA and Europe. Acetal is also notch sensitive, meaning the materials susceptibility to fracture. Acetals have the highest crystallinity (degree of structural order in a solid) of any thermoplastics making it strong and fatigue resistant. This toughness (or lack of ductility) makes it susceptible to fracture where there is a notch, a sudden change in the surface section, a crack, or scratch. Because acetals are notch sensitive, sharp corners must be avoided in part design. This has been an issue in various acetal product designs, including the thread geometry of the water supply coupling nuts and toilet valve triggers, resulting in premature failures.

Many of the plastic components dealt with in subrogation have a tale to tale. Uncovering the material’s "story" may be the key to recovery.