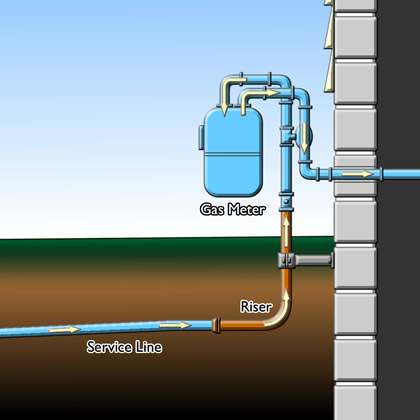

Most commercial and residential properties using natural gas have gas riser pipes which connect the primary distribution service line to the natural gas meter. Although the gas riser connects the utility’s distribution line to the utility’s meter, these risers are typically installed by a sub-contracting plumber during original construction. For this reason, the riser often belongs to the property owner, not the utility.

Most commercial and residential properties using natural gas have gas riser pipes which connect the primary distribution service line to the natural gas meter. Although the gas riser connects the utility’s distribution line to the utility’s meter, these risers are typically installed by a sub-contracting plumber during original construction. For this reason, the riser often belongs to the property owner, not the utility.

Most gas risers consist of a polyethylene tubing inside of a rigid conduit with metal or plastic connectors on both ends. Gas risers are only used in natural gas systems. Liquid propane gas systems utilize copper or black iron pipe to connect the local supply tank directly to the meter.

A natural gas leak originating at a gas riser typically manifests itself in one of two ways: 1) the leaking gas travels through the soil, accumulates in the sump pit or crawlspace, and finds an ignition source which causes an explosion; or 2) the leaking gas migrates up to the surface of the soil and finds an ignition source, resulting in a fire at ground level. Because the gas leak begins underground, oftentimes it is simply overlooked as a potential ignition source.

Gas leaks can originate at gas risers due to both manufacturing defects and installation errors. A common failure method is the over-tightening of the plastic connectors during installation. The over-tightening results in a damaged connector which eventually leaks. Manufacturing defects can occur in a variety of ways ranging from improper materials to anomalies in the riser construction. It is important to quickly identify the cause of the leak in order to avoid any potential claims being barred by the applicable statutes of repose. Asking your expert the difficult questions early on will help to streamline recovery efforts down the road.